Mechanical components often subject to outages

This solution supplies the maintenance, service and R&D departments with strategic information on the status of assets that influence the operation of a single machine or the entire plant.

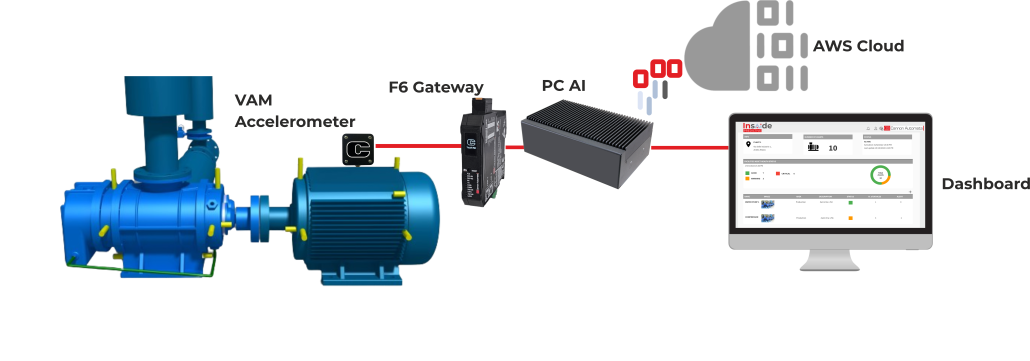

InsAIde Predictive kit includes:

Vibration Analysis Module (VAM) Accelerometer

The Micro Electro Mechanical Systems (MEMS) capacitive and triaxial smart vibration sensor filters the signal and locally transforms acceleration data into the frequency domain using Fast Fourier Transform (FFT).

- Bandwidth: 6 kHz

- Selectable sensitivity: ±2, ±4, ±8 or ±16 g

- Serial communication interface RS485

- Operating temperature: -40°C / +85°C

F6 Gateway

Equipped with a 32-bit ARM Cortex-A8 microprocessor, it is ideal for environments requiring a compact, high- performance, low-power system with the possibility of expansion through I/O modules for inputs from the field.

This, via a 485 bus, manages the configuration of the individual VAM accelerometers and the signal acquisition trigger logic. The information, once processed in real time, is communicated to the AI PC.

PC AI

This high-performance controller with an Nvidia Jetson Orin NX module communicates bidirectionally with the cloud to send data from the field. The predictive model, installed locally via license, operates on this system.

AWS Cloud

The model is trained and verified on the AWS platform before being provided to the client. This optimizes the parameters with the aim of making increasingly accurate predictions.

Dashboard

The information coming from the PC can be viewed from a web browser through simple, intuitive dashboards. This allows departments to build a fully-planned inefficiency-free maintenance strategy. The package can be integrated with our MES maintenance module.