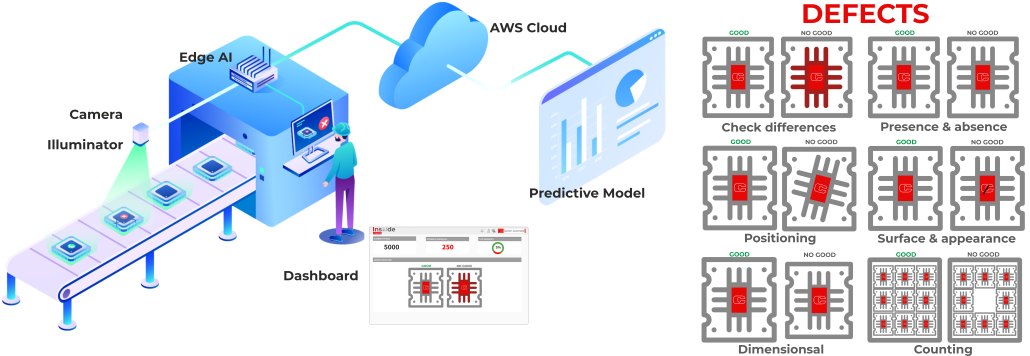

This innovative system is easy to train and validate: the model trains on compliant parts, thus identifying anomalies that deviate from what is acceptable.

An application are capable of verifying the entire production process in real time, detecting a wide variety of product defects:

InsAIde Vision kit includes:

Camera

Equipped with Global Shutter CMOS sensors, a GigE Vision interface and 8 megapixel resolution, our solution is ideal for capturing fast-moving objects with excellent image quality. The camera is robust, compact and highly adaptable to changing light conditions and minimizes motion blur in fast image processing applications, with exposure times starting from 1 μs.

Illuminator

A continuous-use diffused light system, on axis with the camera, eliminates reflections from the lighting rig, ensuring optimal photographic capture.

Edge AI

Images are processed and classified locally by our Edge AI PC, a high-performance system with an Nvidia Jetson Orin NX module based on Linux. This solution guarantees high processing performance through its processor with a 64-bit NVIDIA ARM Cortex CPU and 32-core Tensor GPU.

AWS Cloud

Before operation, the model is trained and verified on the AWS platform. This optimizes the parameters with the aim of making increasingly accurate predictions.

Once ready, it is locally installed on our Edge AI via license.

Dashboard

Information from Edge AI can be viewed from web browsers through simple and intuitive dashboards, providing you constant control over the process and its products to ensure maximum quality. The package can be integrated with our MES Quality module.