For manufacturing, testing and quality control are essential steps. Now more than ever, companies need to evaluate new solutions to the detriment of traditional verification processes which are often linked to manual and inefficient methods that involve the risk of expensive rework, countless waste and frequent product recalls.

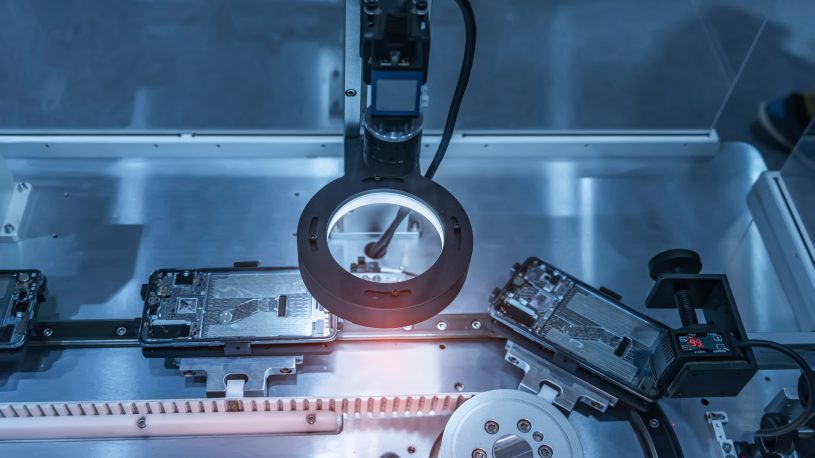

This is why we create machines and systems for quality control at the end of the line.

Automated and customized solutions allow you to verify component quality in real time and manage the data resulting from the processes, guaranteeing high performance in production departments.

These solutions identify non-conformities with extreme simplicity, especially where the high mix and production speed put the finished product’s quality at risk.

Main features

- The system uses the most well-known brands of machine vision AI

- Possible integration of AI-based anomaly detection technology

- Integration of robotic systems

- Consulting

- Design

- Development and production

- Installation and integration

- Assistance and training